Discover the Best Speech Therapy for Kids and Adults

Steps Groups: Empowering Communication, Confidence, and Growth Communication plays a vital role in every aspect of life — from expressing emotions to building relationships and succeeding academically or professionally. When speech, language, or communication difficulties arise, they can impact a person’s confidence, social interactions, and overall quality of life. At Steps Groups, we provide specialized Speech Therapy for kids and adults, offering personalized treatment plans that help individuals communicate more effectively and confidently.

https://medium.com/@stepsgroup....s11/speech-therapy-f

Discover posts

Benefits of Website Maintenance for Business

A well-performing website has become essential for every modern company, regardless of industry or size. Because customers expect fast, reliable digital experiences, ongoing support is crucial to maintaining that standard. Understanding the benefits of website maintenance for business helps owners recognize that a website is more than a digital brochure. It is a living platform that requires consistent care. When maintained properly, it supports credibility, improves performance, and enhances overall user satisfaction. Visit : https://www.pxmediainc.com/5-a....ttractive-benefits-o

Kaufen Sie lange Boho-Kleider

Lange Boho-Kleider sind eine vielseitige Ergänzung Ihrer Garderobe – entdecken Sie ihren Reiz! Diese Kleider strahlen einen freigeistigen Bohème-Charme aus und sind ideal für unterschiedliche Anlässe. Stöbern Sie durch unsere Kollektion, um das perfekte lange Boho-Kleid zu entdecken, das Ihrem individuellen Stil entspricht und Ihrem Outfit einen Hauch von bohèmehafter Eleganz verleiht.

https://boho-lust.de/collections/boho-kleid-lang

Bail Bonds Denton – Fast, Reliable Service by Shawn Cagle's City Hall Bail Bonds

When you need bail bonds Denton families can trust, Shawn Cagle's City Hall Bail Bonds is here to help with fast, dependable support. Our team understands that arrests happen unexpectedly, and we work quickly to secure release with minimal stress. With clear communication, fair rates, and 24/7 availability, we guide you through every step of the bail process. We’re committed to treating every client with respect and urgency, ensuring your loved one returns home as soon as possible. For compassionate service and experienced bail bond professionals in Denton, choose the team that puts your needs first.

Visit at:- https://goo.gl/maps/S59Zqsmr1R8aVoAh7

A keto calculator tool works by calculating your daily calorie requirements and dividing them according to standard keto ratios. To Know more do visit: https://pain-management.hellob....ox.co/7523538/keto-c

Top AI-Powered Google Ads Expert in Bangalore

Boost your ROI with smart campaigns powered by AI. Eflot, the leading digital marketing agency in Bangalore, offers:

Google Ads Management

PPC & Paid Campaigns

Digital Marketing Services in Bangalore

Conversion Optimization

Stop wasting budget and start driving results!

https://eflot.com/

Email ID: service@eflot.com

Contact Number: +91 7996669915

Premium Rechargeable Lamps for Home - Shivalightning

Discover high-quality rechargeable lamps for home at Shiva Lightning. Our energy-efficient, long-lasting lighting solutions ensure reliable brightness during power cuts and daily use. Explore trusted, durable home lighting options designed for comfort and convenience.

Visit us: https://shivalightning.com

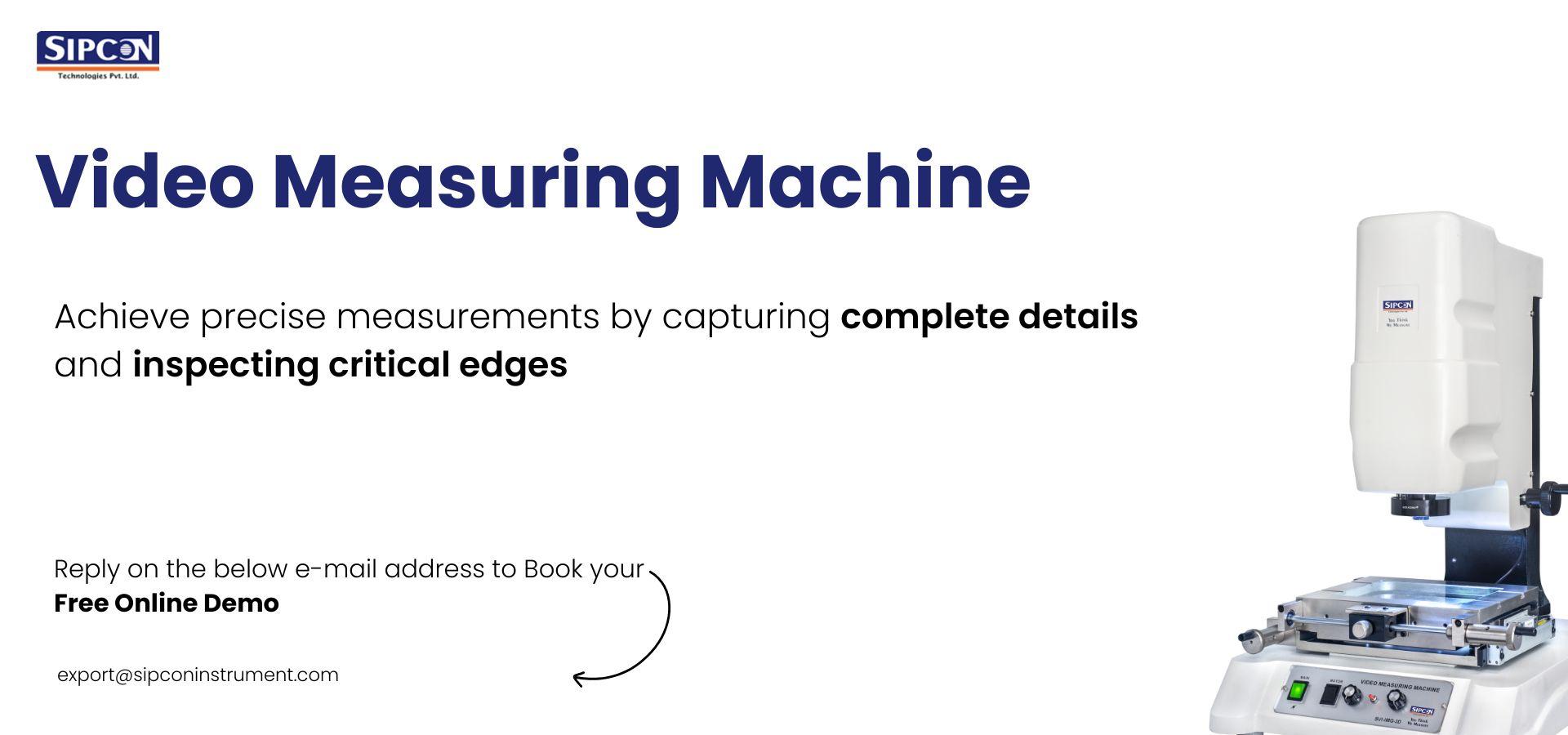

A Beginner’s Guide to Video Measuring Machine Technology

Video Measuring Machine (VMM) technology has become an essential tool in modern quality inspection, offering fast, accurate, and non-contact measurement for a wide range of components. This beginner’s guide explains how VMMs work and why they are widely used across industries like automotive, aerospace, electronics, rubber, and precision engineering. These machines use high-resolution cameras, advanced optics, and powerful software to capture detailed images of parts and analyze their dimensions with exceptional accuracy.

Unlike traditional measuring tools, VMMs eliminate human error and allow operators to measure small, complex, or delicate components without physical contact. They offer 2D and 3D measurement capabilities, automated inspection routines, and digital reporting that improves both productivity and consistency. Beginners will appreciate their user-friendly interfaces, easy-to-learn workflows, and ability to store and recall inspection programs for repetitive tasks.

Whether you’re upgrading your inspection process or exploring advanced metrology solutions, understanding video measuring machine technology helps you make informed decisions. With the right VMM, manufacturers can achieve higher precision, faster throughput, and improved quality control—making these systems a smart investment for any industry focused on accuracy and efficiency.

Read our blog for more details: https://www.sipconinstrument.c....om/blog/video-measur

Laptop Rental Indore | Affordable Laptop & IT Equipment on Rent – Varnet Solutions

Looking for reliable laptop rental in Indore? Varnet Solutions offers high-performance laptops, desktops, and IT equipment on rent for businesses, students, events, and startups. Flexible plans, doorstep delivery, quick support, and premium brands available. Book your laptop rental today! Call Us: 8962424659.

Visit Us: https://varnetsolutions.com