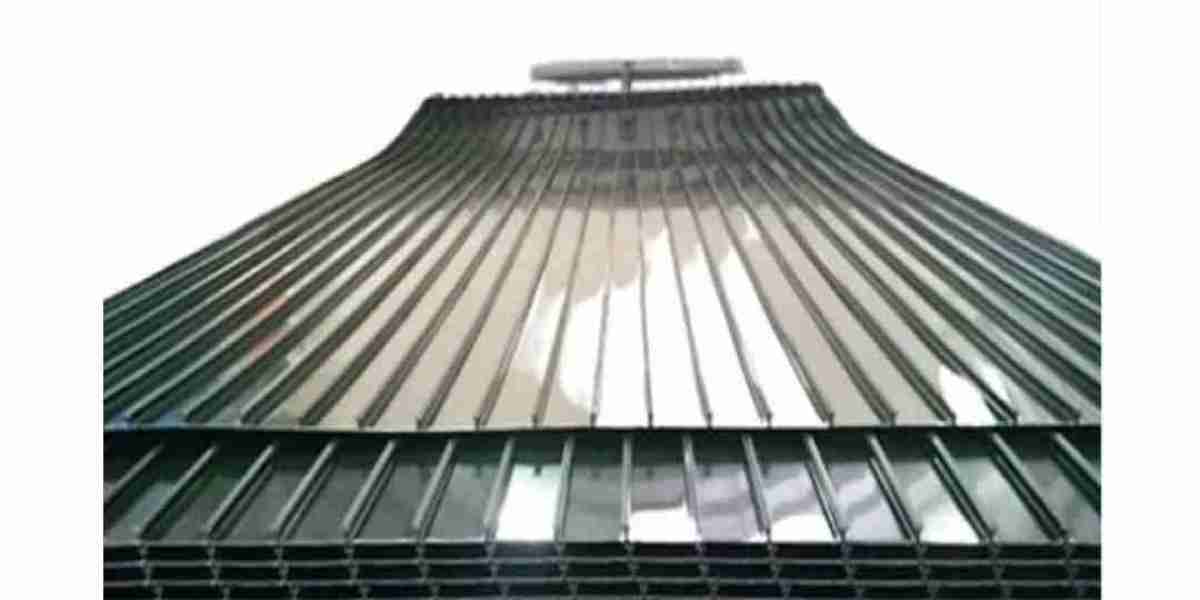

Introduction to HDPE T-Rib Liner Sheets

High-Density Polyethylene (HDPE) T-Rib liner sheets have emerged as a versatile and durable solution for various industrial applications. With their unique ribbed design, these liners offer enhanced structural integrity, which sets them apart from traditional flat liners. The rigidity provided by the T-Rib structure not only enhances strength but also improves stability, making them ideal for environments where physical stresses and chemical exposure can be significant. Industries spanning agriculture, aquaculture, construction, and waste management are increasingly turning to Mahira Polyglobal LLP for their effective containment solutions, which promise to safeguard both human health and the environment.

The Advantages of HDPE T-Rib Liners

The design of HDPE T-Rib liners confers numerous advantages that appeal to various sectors. First and foremost, these liners exhibit exceptional resistance to chemicals, making them suitable for applications involving corrosive materials such as fertilizers, pesticides, and industrial chemicals. Their high tensile strength allows them to withstand the weight of substantial loads without sagging or deforming. Furthermore, the ribbed texture enhances drainage, which is essential in agricultural applications where water retention can lead to soil saturation and plant health issues. The UV-resistant properties of HDPE T-Rib liners also mean they can endure long-term exposure to sunlight without degrading, making them a smart choice for outdoor projects.

Another significant aspect of HDPE T-Rib liners is their environmental benefits. Being made of recyclable materials, these liners not only reduce waste but also contribute to a more sustainable approach to construction and agricultural practices. Companies are gravitating toward using such liners not only for compliance with environmental regulations but also for fostering an eco-friendly image which is increasingly important to consumers.

Applications of HDPE T-Rib Liners Across Industries

The multifunctionality of HDPE T-Rib sheet price allows for extensive applications across various industries. In agriculture, for instance, these liners are used extensively as pond liners, helping to create irrigation reservoirs that retain water effectively. They also play a crucial role in aquaculture, providing a safe environment for fish and other aquatic life. Moreover, in the construction industry, the liners are employed for retaining earth, preventing erosion, and managing stormwater runoff. Mining companies rely on HDPE T-Rib liners to safeguard against hazardous material leaks, thus protecting groundwater and surrounding ecosystems.

In waste management, the importance of HDPE T-Rib liners cannot be understated. They serve as critical barriers in landfills and containment ponds, preventing the seepage of leachate into the soil and groundwater, thereby preventing long-term environmental damage. Residential landscaping projects also benefit from these liners when creating water features, such as ponds or fountains, enhancing aesthetics while ensuring the durability of the installations.

Choosing the Right Lining Sheet Manufacturers

Selecting the right lining sheet manufacturers is vital for achieving the best possible outcomes with HDPE T-Rib liners. Quality should be paramount in the selection process, as inferior products can lead to operational failures and potential environmental hazards. When evaluating lining sheet manufacturers, it is essential to research their credibility, reputation, and past performance. Look for manufacturers who provide clear specifications on their products, adhere to industry standards, and have rigorous quality control processes in place.

Certifications can be an excellent indicator of a manufacturer's commitment to quality. ISO certifications, for example, ensure that the manufacturer complies with international production standards. Engaging with manufacturers who have a proven track record of successful project completions can also offer peace of mind, as their experience may lead to better recommendations and solutions tailored to specific needs, enhancing project effectiveness and reliability.

The Role of HDPE T-Rib Sheet Suppliers

In addition to choosing the right manufacturers, identifying competent HDPE T-Rib sheet suppliers is crucial for successful procurement. Suppliers serve as the link between manufacturers and end-users, ensuring that high-quality products reach their destination promptly and efficiently. Reliable suppliers not only provide access to quality products but also offer valuable support and guidance through the purchasing process.

When selecting HDPE T-Rib sheet suppliers, it’s essential to consider their customer service, product availability, and delivery performance. A responsive supplier who understands your industry will provide better service by addressing concerns and facilitating smooth transactions. Moreover, establishing a long-term relationship with a reputable supplier can lead to additional benefits, such as discounted rates, technical support, and priority access to new products or innovations, which can enhance the overall procurement experience.

Environmental Sustainability of HDPE T-Rib Liners

The ongoing emphasis on sustainability has influenced various industries to reconsider their material choices. HDPE T-Rib liner sheets installation align well with sustainable practices due to their durability and ability to be recycled. Unlike traditional materials that may require frequent replacements, HDPE T-Rib liners can last for years, leading to significant waste reduction over time. By opting for these liners, organizations can minimize environmental footprints, which is increasingly a matter of public concern.

Moreover, the production of HDPE liners has become more environmentally friendly with advancements in manufacturing technologies. Many lining sheet manufacturers prioritize eco-conscious techniques in their production, focusing on reducing emissions, energy usage, and resource consumption during the manufacturing process. This commitment not only helps meet regulatory standards but also enhances the credibility of companies within environmentally conscious markets.

Installation and Maintenance of HDPE T-Rib Liners

Proper installation and maintenance of HDPE T-Rib liners are critical steps that can significantly influence their performance and lifespan. The installation process should begin with comprehensive site preparation to ensure a smooth foundation. This includes clearing the area of debris and sharp objects that could compromise the liner. When installing the HDPE T-Rib liner, attention to detail is crucial; ensuring that seams are properly sealed and that the liner fits snugly will prevent leaks and extend the material's life.

Once installed, regular maintenance is essential for maximizing the liner's effectiveness. Periodic inspections should be conducted to check for signs of wear, improper drainage, or damage caused by environmental factors. Proper care, including cleaning the surface and ensuring that chemical spills are managed promptly, will help extend the liner's usability. Documentation of installation procedures and maintenance activities is also beneficial, as it enables accountability and can assist in claims if issues arise.

Conclusion: The Future of HDPE T-Rib Liners

The future of T-Rib HDPE liner sheets technology appears promising, given the growing awareness of sustainable practices across various sectors. As industries evolve, the demand for reliable and environmentally friendly containment solutions is likely to increase. Manufacturers and suppliers are expected to focus on enhancing the quality and capabilities of HDPE T-Rib liners while incorporating innovative technologies that further benefit their users. For businesses, the adoption of HDPE T-Rib liners not only addresses current operational needs but also positions them favorably in a market that is increasingly focused on environmental responsibility and sustainability.

Frequently Asked Questions

1. What is the primary benefit of using HDPE T-Rib liners?

The primary benefit of HDPE T-Rib liners is their robust design, which combines chemical resistance, structural integrity, and UV stability, making them ideal for various applications, including agriculture, aquaculture, and waste management.

2. How do I select a reliable lining sheet manufacturer?

To select a reliable lining sheet manufacturer, research their track record, look for industry certifications, check their past projects, and read customer reviews to ensure that they adhere to high-quality standards.

3. Are HDPE T-Rib liners environmentally friendly?

Yes, HDPE T-Rib liners are environmentally friendly as they are made from recyclable materials, designed for longevity, and can help mitigate environmental damage in applications like landfills and water retention.

4. What should I consider when maintaining HDPE T-Rib liners?

When maintaining HDPE T-Rib liners, regularly inspect for signs of wear or damage, ensure proper drainage, clean the surface to prevent contaminants, and document maintenance activities for future reference.