PUF Panel Cost Guide 2025: Complete Pricing Breakdown by Thickness & Application

Understanding Modern Insulation Solutions

The construction industry continues to evolve with innovative building materials that offer superior thermal performance and cost efficiency. Understanding the financial investment required for quality insulation helps builders and property owners make informed decisions. This comprehensive guide examines pricing structures, material specifications, and application-specific considerations to provide clarity on budgeting for your next project.

Current Market Pricing Analysis

PUF Panel Cost @ https://mountroof.com/puf-panel-price/ varies significantly based on multiple factors including thickness, density, and manufacturing quality. As of 2025, standard panels range from ₹350 to ₹850 per square meter depending on specifications. Thickness options typically include 50mm, 75mm, 100mm, and 150mm variants, with each increment affecting both insulation performance and pricing. Manufacturers also factor in polyurethane foam density, which directly impacts thermal resistance values and structural integrity.

Roofing Applications and Pricing

PUF Sandwich roofing Panel Price @ https://mountroof.com/puf-sand....wich-wall-panel-pric reflects specialized engineering for overhead applications. These panels incorporate weather-resistant exterior coatings and reinforced cores designed to withstand environmental stress. Current market rates for roofing-grade panels start at ₹420 per square meter for 50mm thickness and can exceed ₹950 per square meter for premium 150mm options. The pricing includes galvanized steel facings with protective coatings that ensure longevity in diverse climatic conditions.

Material Specifications and Variants

Sheet-Based Solutions

PUF Sheets represent a versatile category within the insulation market, offering flexibility for customized applications. Available in various dimensions, these sheets allow for precise fitting in renovation projects and specialized installations. Standard sheet sizes measure 1000mm in width with lengths extending from 2400mm to 12000mm. Pricing for sheet configurations typically falls between ₹380 and ₹720 per square meter, influenced by core density and facing material quality.

Comprehensive Panel Overview

Core Technology and Construction

PUF Panel construction involves a sophisticated manufacturing process where polyurethane foam is injected between two metal facings under controlled pressure and temperature. This creates a monolithic structure with exceptional strength-to-weight ratios. The rigid foam core provides R-values ranging from 6.5 to 8.0 per inch, significantly outperforming traditional insulation materials. Modern panels feature tongue-and-groove interlocking systems that minimize thermal bridging and ensure seamless installation.

Thickness-Based Price Breakdown

Standard Thickness Options

Different project requirements demand varying insulation levels. For moderate climate zones, 50mm panels offer adequate thermal protection at entry-level pricing. Cold storage facilities and temperature-controlled environments typically specify 100mm or 150mm panels to maintain consistent internal conditions. Industrial applications often require 75mm panels that balance cost efficiency with performance requirements. Each 25mm thickness increment generally adds ₹80-₹120 per square meter to the base price.

Application-Specific Considerations

Industrial and Commercial Use

Manufacturing facilities, warehouses, and commercial buildings represent primary applications for these insulation systems. The choice between wall panels and roofing panels depends on structural requirements and thermal management goals. Wall panels typically feature different edge profiles compared to roofing variants, accommodating vertical installation dynamics. When selecting suppliers, companies like Mount @ https://mountroof.com/ have established reputations for delivering consistent quality and competitive pricing across diverse project scales.

Installation and Total Project Costs

Beyond Material Pricing

Complete project budgeting must account for installation labor, structural supports, and accessories. Professional installation typically adds 30-40% to material costs, though this investment ensures proper thermal performance and warranty compliance. Fasteners, sealants, and flashing components contribute an additional ₹45-₹85 per square meter. Projects requiring specialized fire-rated panels or acoustic variants should anticipate premium pricing of 15-25% above standard configurations.

Making Informed Decisions

Quality insulation represents a long-term investment in building performance and operational efficiency. While initial costs merit careful consideration, the lifecycle benefits of superior thermal control and reduced energy consumption provide substantial returns. Consulting with experienced suppliers and reviewing manufacturer specifications ensures optimal material selection for your specific application requirements.

Mount Roofing Structures Pvt Ltd

The 2025 Multiwall Polycarbonate Greenhouse Guide: Expert Testing, Ratings & Installation Best Practices

Understanding Modern Greenhouse Glazing Materials

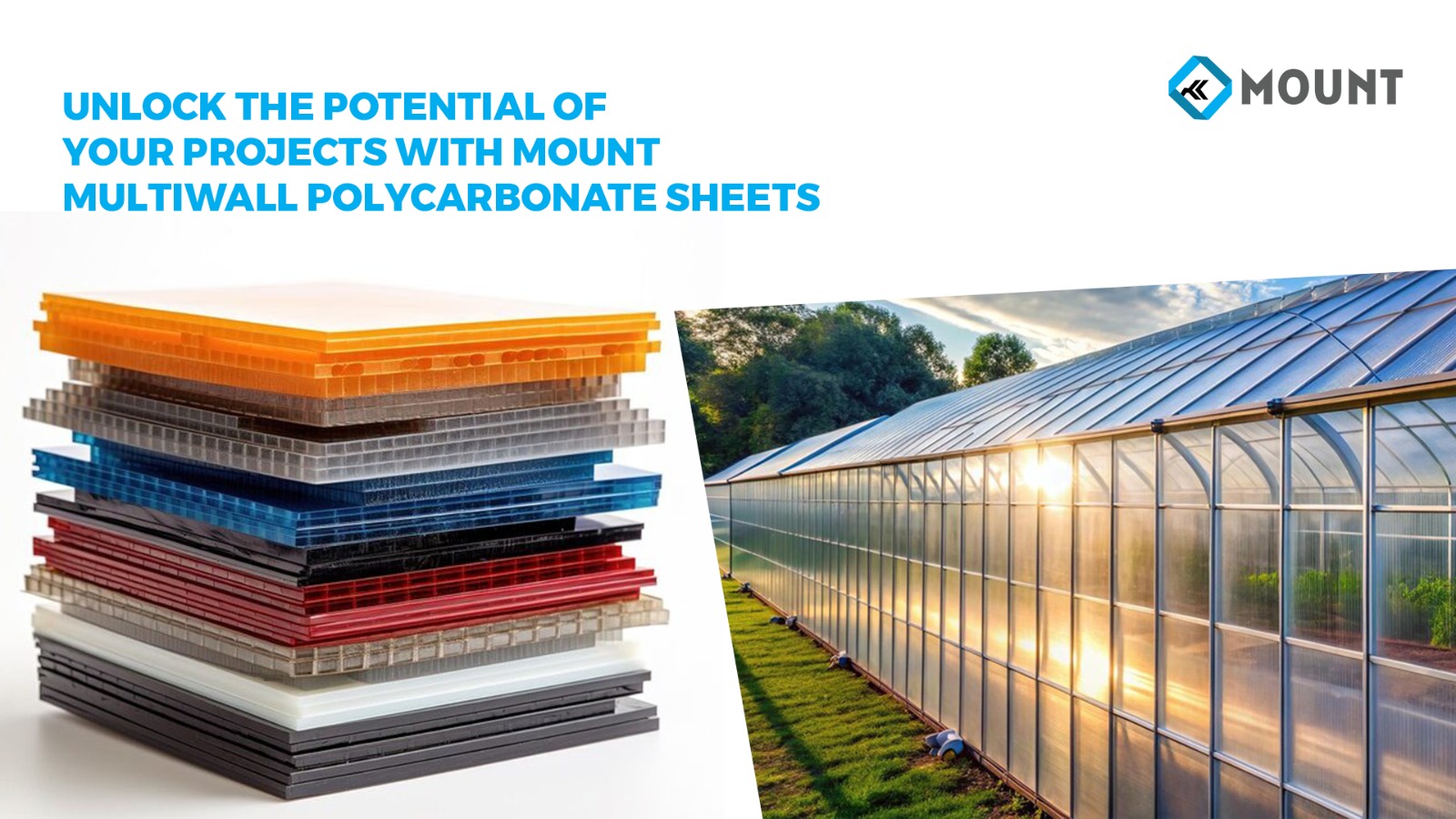

Selecting the right glazing material determines your greenhouse's performance, energy efficiency, and crop success. The Best Multiwall Polycarbonate Sheets For Greenhouses @ https://mountroof.com/mount-mu....ltiwall-polycarbonat have revolutionized how growers approach climate control and light management. These advanced materials offer superior insulation compared to traditional glass while maintaining excellent light transmission rates. Through extensive field testing across various climate zones, we've identified key performance indicators that matter most to serious growers.

The Science Behind Cellular Construction

Polycarbonate Sheets @ https://mountroof.com/mount-li....te/polycarbonate-she utilize a unique cellular structure that creates air pockets between layers, providing exceptional thermal insulation. This engineering breakthrough allows greenhouse operators to maintain stable temperatures with reduced heating costs. The material's impact resistance—nearly 200 times stronger than glass—makes it ideal for regions experiencing hail or extreme weather events. Modern manufacturing processes ensure consistent quality and UV protection, which extends panel lifespan by up to 15 years or more.

Material Variations and Performance Metrics

Multi-Layer Panel Systems

Multiwall Polycarbonate Sheets come in various configurations, from twin-wall to five-wall designs, each offering distinct advantages. Twin-wall panels typically provide an R-value of 1.7, while triple-wall and quad-wall options can achieve R-values exceeding 2.5. The increased number of walls reduces heat transfer but may slightly diminish light transmission. Professional growers must balance insulation needs against crop light requirements when selecting panel thickness and wall configuration.

Thickness Considerations for Different Applications

Panel thickness directly impacts both insulation properties and structural integrity. Common thicknesses range from 4mm for small hobby greenhouses to 16mm for commercial operations in cold climates. Thicker panels offer better energy efficiency but require stronger framing support. Installation spacing should be calculated based on local snow loads and wind pressure ratings to ensure structural safety throughout the season.

Alternative Glazing Options

Solid Polycarbonate Sheets present a different approach for specific greenhouse applications. While lacking the insulating air chambers of multiwall designs, solid panels offer maximum light transmission—up to 90% clarity—making them suitable for propagation houses or tropical plant cultivation. These sheets excel in applications where light quality trumps thermal efficiency. Their smooth surface also simplifies cleaning and maintenance compared to textured alternatives.

Professional Installation Guidelines

Mounting Framework and Best Practices

Proper installation begins with selecting appropriate framing systems designed specifically for polycarbonate glazing. Aluminum extrusions with thermal breaks prevent condensation while accommodating thermal expansion—a critical factor often overlooked by inexperienced installers. When you mount polycarbonate panels, always orient them with flutes running vertically to facilitate condensation drainage and prevent moisture accumulation inside the cellular channels.

Sealing and Weather Protection

Edge sealing requires specialized tape systems that block moisture infiltration while allowing trapped air to escape. Never seal panels completely—this creates internal condensation problems that degrade performance over time. Professional-grade installation includes proper flashing details at ridge lines, eaves, and side walls. These elements work together to create a weathertight envelope that protects crops while maximizing the glazing material's inherent advantages.

Maintenance and Long-Term Performance

Regular maintenance extends panel lifespan significantly. Annual inspection of seals and fasteners prevents small issues from becoming costly repairs. Cleaning should use only mild soap solutions—never abrasive cleaners or high-pressure washing that can damage UV protective coatings. Proper maintenance ensures panels deliver consistent performance throughout their rated service life, protecting your investment in greenhouse infrastructure.

PUF Sandwich Roofing Panel Price Guide 2025: Complete Cost Breakdown by Thickness & Brand

Understanding the Market Landscape

The construction and industrial sectors are witnessing a significant shift toward energy-efficient building solutions. Polyurethane foam sandwich panels have emerged as a preferred choice for roofing applications due to their superior insulation properties and structural integrity. When evaluating the PUF Sandwich roofing Panel Price, @ https://mountroof.com/puf-sand....wich-wall-panel-pric buyers should consider multiple factors, including thickness specifications, core density, and metal sheet quality. Current market rates typically range from ₹350 to ₹850 per square meter, depending on these variables.

Factors Influencing Pricing

Several elements contribute to the overall investment required for these insulated panels. The PUF Panel Cost @ https://mountroof.com/puf-panel-price/ varies significantly based on the thickness of the polyurethane core, which commonly ranges from 50mm to 150mm. Thicker panels provide better thermal resistance but command higher prices. Additionally, the gauge of the steel cladding—whether 0.4mm, 0.5mm, or 0.6mm—directly impacts durability and cost. Brand reputation, manufacturing standards, and certifications also play crucial roles in price determination.

Specialized Applications and Premium Segments

Certain industries require panels that meet stringent quality standards, which exceed those of conventional roofing applications. Clean Room Puf Sandwich Panels are specifically engineered for pharmaceutical facilities, hospitals, and food processing units where hygiene and contamination control are paramount. These panels feature anti-bacterial coatings, seamless joints, and comply with international cleanroom classifications. The precision manufacturing and additional quality certifications result in premium pricing, typically 20-30% higher than standard roofing panels.

Industry-Specific Requirements

Temperature-controlled environments demand specialized insulation solutions with precise thermal performance characteristics. Businesses operating in the refrigeration sector often collaborate with Cold Storage and Cold Room Manufacturers who provide comprehensive turnkey solutions, including panel supply, installation, and temperature monitoring systems. These manufacturers typically offer bundled pricing that includes panels with enhanced thermal efficiency ratings, specialized door systems, and professional installation services. The integrated approach ensures optimal performance for preserving perishable goods.

Thickness-Based Cost Analysis

H3: 50mm Panels

Entry-level thickness suitable for moderate climate zones and non-critical applications. Price range: ₹350-₹450 per square meter.

H3: 75mm Panels

Mid-range option balancing cost and insulation performance. Price range: ₹450-₹600 per square meter.

H3: 100mm and Above

Premium thickness for extreme climate conditions and specialized facilities. Price range: ₹600-₹850 per square meter.

Quality Considerations

When sourcing these building materials, quality should never be compromised for cost savings. Reputable manufacturers like Mount ensure their products meet international standards for fire resistance, thermal conductivity, and structural stability. Proper due diligence includes verifying certifications, reviewing test reports, and examining sample panels before bulk procurement.

Installation and Long-Term Value

The initial purchase price represents only one component of the total ownership cost. Professional installation, maintenance requirements, and energy savings over the panel's lifecycle significantly impact overall value. High-quality panels with superior insulation properties reduce heating and cooling expenses, often recovering the initial premium within 3-5 years through energy cost reductions.

Making an Informed Decision

Smart procurement requires comparing multiple quotations, understanding warranty terms, and evaluating the supplier's track record. Request detailed specifications, including core density (typically 38-42 kg/m³), thermal conductivity values, and fire rating certificates. Consider the total project scope—larger orders generally qualify for volume discounts, while customized colors or special coatings may incur additional charges.

The investment in quality insulated roofing panels delivers tangible benefits through enhanced building performance, reduced operational costs, and improved occupant comfort. By understanding the pricing structure and quality differentiators, buyers can make decisions that balance immediate budget constraints with long-term value creation.

Why Thrissur Industries Are Switching to Pre-Engineered Steel Buildings: A Kerala Case Study

The Industrial Transformation in Kerala's Cultural Capital

Thrissur, historically known as the cultural capital of Kerala, is experiencing a significant industrial transformation driven by modern construction methodologies. Manufacturing facilities across the region are increasingly seeking efficient infrastructure solutions that can accommodate rapid growth and changing operational demands. The construction sector has witnessed a paradigm shift, with businesses prioritizing speed, durability, and cost-effectiveness through Pre-Engineered Steel Building Supplier in Thrissur @ https://mountroof.com/pre-engi....neered-building-manu partnerships. Industries ranging from automotive components to food processing are reconsidering their infrastructure choices, moving away from conventional building methods. This transition reflects a broader understanding of how modern construction technologies can enhance operational efficiency while ensuring long-term sustainability and value creation for businesses operating in Kerala's dynamic industrial landscape.

Understanding the Local Supply Ecosystem

The growing demand for modern steel structures has created a robust supply ecosystem within Thrissur and the surrounding regions. Businesses now have access to local expertise that understands Kerala's specific climatic challenges, regulatory requirements, and industrial needs. Working with Pre-engineered Metal Building Manufacturers @ https://mountroof.com/pre-engineered-buildings/ provides distinct advantages, including faster project turnaround times, readily available technical support, and reduced logistics expenses. Local suppliers offer personalized consultation services, helping businesses select appropriate designs and specifications that align with their operational requirements. This proximity enables better communication throughout the project lifecycle, from initial planning stages through construction completion and eventual maintenance needs.

The Manufacturing Excellence Behind Modern Structures

Quality and precision form the foundation of successful industrial construction projects. The components used in contemporary steel buildings undergo rigorous fabrication processes in controlled factory environments, ensuring consistent standards and superior structural integrity. Pre-Engineered Steel Building Supplier in Thrissur employs advanced engineering software and automated production systems that deliver accuracy impossible to achieve through traditional on-site construction methods. This factory-based approach eliminates human errors, reduces material wastage, and ensures that every component meets exact specifications. The manufacturing process incorporates stringent quality checks at multiple stages, guaranteeing that the final structure will perform reliably under Kerala's challenging monsoon conditions and humid coastal environment.

Regional Expertise and Customization Capabilities

Understanding local market dynamics and regional construction challenges requires specialized knowledge that comes from years of experience operating within specific geographic areas. A pre-engineered building Manufacturer In Thrissur brings invaluable insights about soil conditions, wind loads, seismic considerations, and weather patterns unique to central Kerala. This regional expertise translates into better-designed structures that account for local factors often overlooked by distant suppliers. Customization capabilities extend beyond basic structural requirements to include specific features like enhanced corrosion protection for coastal proximity, optimized ventilation systems for tropical climates, and designs that accommodate future expansion plans. Local manufacturers maintain relationships with regional authorities, streamlining the approval process and ensuring compliance with state-specific building codes.

Versatility Across Industrial Applications

Modern steel construction methodologies offer remarkable adaptability across diverse industrial sectors and applications. Pre-engineered buildings serve warehousing operations, manufacturing plants, logistics facilities, cold storage units, and commercial complexes with equal effectiveness. The clear-span design philosophy eliminates internal load-bearing columns, creating expansive open spaces that maximize operational flexibility and workflow efficiency. Industries appreciate the ability to modify interior layouts without compromising structural integrity, accommodating evolving production processes and equipment changes. These structures can incorporate specialized features such as overhead cranes, mezzanine levels, insulated panels, and sophisticated ventilation systems. The modular nature enables phased construction approaches, allowing businesses to expand incrementally as their operations grow without disrupting existing facilities.

Success Stories from Thrissur's Industrial Corridor

Several prominent manufacturing and logistics companies operating in Thrissur have successfully transitioned to modern steel building solutions, reporting measurable improvements in operational efficiency and cost management. These early adopters have documented benefits, including reduced construction timelines, lower maintenance expenses, and improved working environments for employees. Among the suppliers serving this growing market, Mount has established a strong presence by consistently delivering quality structures that meet rigorous industrial standards while providing comprehensive support throughout the project lifecycle. The positive experiences shared by these pioneering companies have encouraged broader industry adoption, creating momentum for the continued modernization of industrial infrastructure across the region.

Conclusion: Strategic Infrastructure Investment

The widespread adoption of advanced steel construction methods in Thrissur represents more than a temporary trend—it reflects fundamental changes in how progressive businesses approach infrastructure investment. Industries evaluating their construction options increasingly recognize that initial cost considerations must be balanced against long-term operational advantages, maintenance requirements, and adaptability to future needs. As Kerala's industrial sector continues expanding, the choice of construction methodology will significantly impact competitiveness and operational success. The evidence from Thrissur's industrial transformation demonstrates that modern steel building solutions deliver tangible value across multiple dimensions, positioning forward-thinking companies for sustained growth in an increasingly competitive business environment.

The Complete Guide to Pre-Engineered Metal Buildings in Coimbatore: Cost, Benefits & Top Contractors

Understanding Modern Construction Solutions

The construction industry in Coimbatore has witnessed a significant transformation with the adoption of modern building technologies. These structures are designed and fabricated in controlled factory environments before being transported to the site for assembly, ensuring precision and quality at every stage of construction. The shift towards prefabricated solutions has revolutionized how industrial and commercial facilities are built across the region.

The Growing Demand for Construction Expertise

Coimbatore's industrial landscape has evolved rapidly, creating substantial demand for efficient construction methods. Pre-engineered metal Building Contractors in Coimbatore @ https://mountroof.com/pre-engi....neered-building-manu play a crucial role in meeting this demand by delivering projects that combine structural integrity with cost-effectiveness. The city's strategic location as a manufacturing hub makes it an ideal market for such construction solutions, where time and budget constraints often determine project success.

Manufacturing Excellence in Steel Construction

The quality of any construction project depends heavily on the manufacturing standards maintained during fabrication. Pre-engineered Metal Building Manufacturers @ http://mountroof.com/pre-engin....eered-building-manuf utilize advanced technology and engineering practices to create components that meet international quality standards. These facilities employ computer-aided design systems and precision machinery to ensure that each structural element fits perfectly during on-site assembly, significantly reducing construction time.

Specialized Storage Solutions

Modern businesses require versatile storage facilities that can accommodate diverse operational needs. Pre-Engineered Multi-Storage Building Manufacturers in Coimbatore specialize in creating customized solutions for warehouses, distribution centers, and logistics facilities. These structures offer design flexibility, allowing for mezzanine floors, multiple storage levels, and efficient space utilization that traditional construction methods struggle to achieve economically.

Versatility of Modern Building Systems

Pre-engineered buildings have emerged as a practical solution for industrial, commercial, and warehousing needs across the region. These construction systems offer remarkable adaptability, accommodating various architectural requirements while maintaining structural efficiency. The modular nature allows for future expansions and modifications without compromising the integrity of the original structures.

Cost Advantages of Modern Construction

Budget considerations remain paramount for any construction project. Metal building systems typically cost 30-40% less than conventional construction methods due to reduced material waste, faster installation, and lower labor requirements. The controlled manufacturing environment eliminates weather-related delays, ensuring projects stay on schedule and within budget projections.

Durability and Maintenance Benefits

Long-term value extends beyond initial construction costs. These structures resist corrosion, termites, and weather damage far better than traditional materials. The maintenance requirements remain minimal throughout the building's lifespan, with protective coatings lasting decades before requiring any attention. This durability translates into lower total ownership costs over the facility's operational life.

Speed of Construction

Time represents money in the construction industry. Metal building projects can be completed in half the time required for conventional construction. Foundation work proceeds simultaneously with component fabrication, and the actual assembly typically takes just weeks rather than months. This rapid deployment allows businesses to commence operations sooner, generating revenue earlier than traditional construction timelines would permit.

Environmental Sustainability

Sustainability concerns significantly influence modern construction decisions. Steel structures are 100% recyclable, creating minimal construction waste. The energy efficiency of these buildings reduces operational costs through improved insulation and natural lighting options. Many organizations choose these solutions specifically for their reduced environmental footprint and alignment with green building standards.

Choosing the Right Construction Partner

Selecting an experienced construction partner ensures project success from design through completion. Mount has established itself as a reliable name in the industry, bringing technical expertise and project management capabilities to every engagement. The right partner understands local regulations, soil conditions, and climate-specific considerations in Coimbatore, ensuring structures perform optimally throughout their service life.

Conclusion

The adoption of modern building technologies continues to reshape Coimbatore's construction landscape. These solutions offer compelling advantages in cost, speed, durability, and sustainability, making them increasingly attractive for a range of applications. As the city continues its industrial expansion, such construction methods will likely play an even more significant role in shaping its infrastructure.